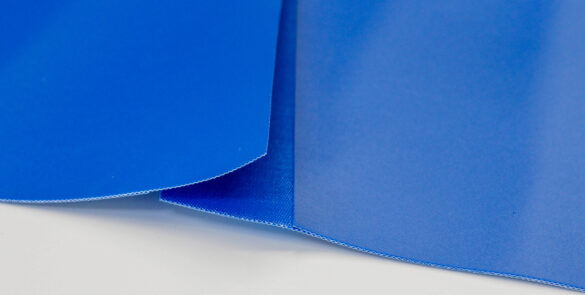

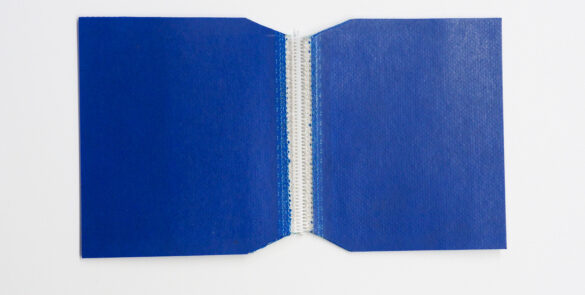

A proven heavy-duty splice for thermo-plastic belting utilizing polyurethane as the bonding agent. Lap area is the same thickness as the belt and uniformly smooth.

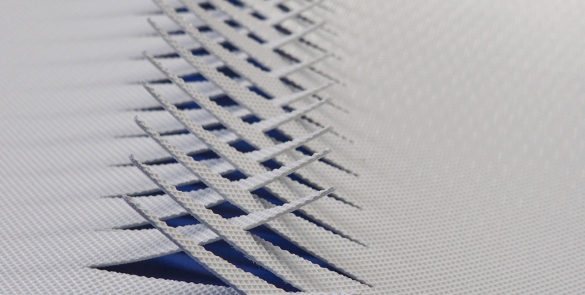

Similar to the single finger splice. Staggered die cut vulcanized together to create a strong, extremely flexible splice.

This splice serves as an alternative to the conventional finger splice that gives more flexibility width wise. A splice commonly used on belts that form bagels.

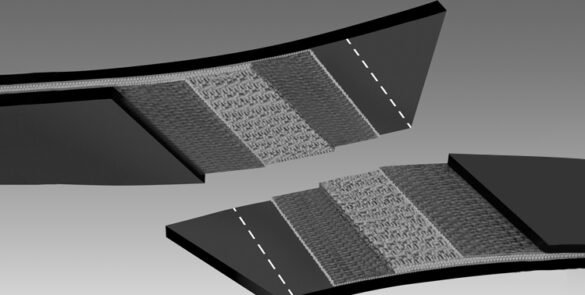

This splice is used on belts with multiple plies. The belt is hot vulcanized using uncured rubber or thermoplastic as a bonding agent.

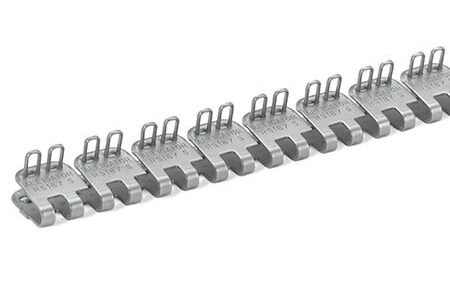

Individual clips are installed via a special machine with minimal damage to the belt and joined via a pin. It provides a smooth joint that is excellent for trough conveyors and small pulleys.

Provides a strong splice resistant to impact damage and a smooth, unrippled joining that makes the hinge inserting easy. The staples work between carcass fibers without severing them. Most commonly used in endless belt applications conveying heavy bulk and irregular items.

Strips of steel with teeth that are installed into the belting and jointed via a pin. A popular style for its ease of installation.

Ideal nonmetallic mechanical splice for small-pulley, low profile applications. Unique hinge design allows use on pulleys and nose bars as small as 5/8″ diameter and as thick as 3/16″. Resists corrosion and heat.

Comes in white and black, nonmetallic compounds for a variety of conveying situations. Fasteners feature beveled edges and counter-sunk pockets in bottom of fastener to protect rivets. Fasteners are either installed by the factory or in the field with special tools.

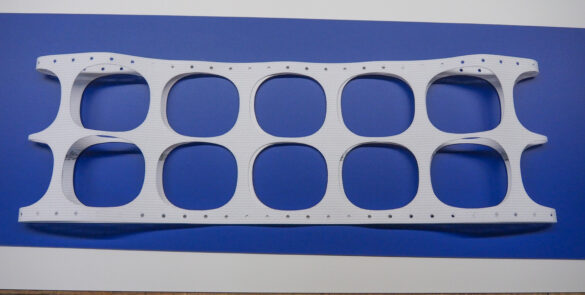

Our depanner belts are ideal for in-line depanning of a wide variety of baked products such as bread, buns and pizza. Depanner belts are a safe and efficient solution for industrial bakeries and will perform even when dealing with varying and complex surfaces.

Belts of custom shapes and sizes used to create dumplings and other dough wrapped or stuffed foods.

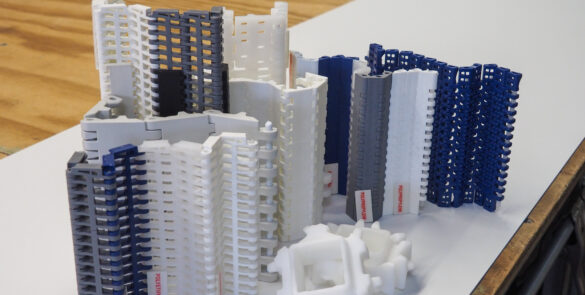

We have hundreds of variations of plastic modular belts to choose from, the largest in Southern California. Inquire with a Western Belting Tech.

With access to cleats of all shapes and sizes including V-shaped, Y-shaped, and rectangular, Western Belting Innovation’s cleats improve the belt’s ability to handle steep inclines or to prevent materials from slipping or falling off the belt during transport. Our V-guides, grooves or tracks that are added to the underside of the belt to help keep it running straight and centered on the conveyor system, are made from durable materials that can stand the test of time.

Our power turn belts, also known as curved belts, are designed to navigate smooth turns in a conveyor system, typically at angles ranging from 15 to 180 degrees. Our belts are made from a variety of materials, including rubber, PVC, and urethane, and are available in a range of sizes and configurations to suit different applications.

Homogeneous/Monolithic belting offers an innovative solution to the limitations of traditional conveyor belts. Its design allows for use in wet and even submerged conditions without off-tracking or the need for friction rollers. This reduces the need for costly conveyor design modifications and brings the food processing industry closer to providing safe and affordable food for all. The belts are FDA/USDA/USDA Dairy approved and comply with EC regulations. Additionally, they support HACCP principles and are ideal for CIP procedures. They are highly resistant to wear and cutting and impervious to water, oils, and other fluids. Installation is easy and minimizes contamination of the work area, and if damaged, the belts can be repaired efficiently by closing tears or replacing sections.

A Teflon conveyor belt, also known as a PTFE (polytetrafluoroethylene) conveyor belt, is a type of high-performance belt that is resistant to extreme temperatures, chemicals, and abrasion. It is often used in industrial applications where materials need to be transported through ovens, freezers, or other extreme environments. Teflon conveyor belts are known for their durability, reliability, and low coefficient of friction, making them ideal for conveying sticky or viscous materials.

Wire conveyor belts are a type of belt made of interwoven metal wires that form a continuous mesh, allowing for airflow and drainage. They are often used in industrial applications such as food processing, baking, and automotive manufacturing, where the belt needs to withstand high temperatures, heavy loads, and exposure to chemicals. Wire conveyor belts offer excellent strength, durability, and easy cleaning, making them a popular choice in industries where hygiene and cleanliness are essential.